Belt filters

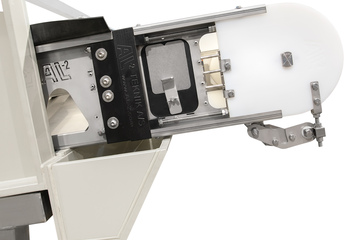

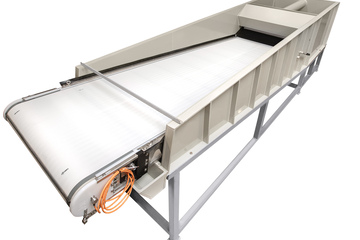

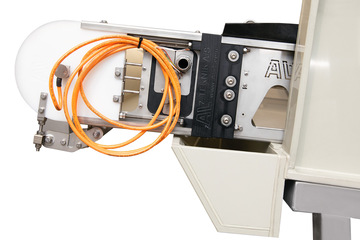

Belt filter - MP-BF

Equipment, used for mechanical pre-treatment or sludge thickening withMechanical filtration represents an efficient as well as economical and environmentally-friendly method to remove solids when treating process and waste waters. The MP-BF sieve-belt filter is a solution suitable for filtering water in many areas and industrial sectors.

Mechanical filtration represents an efficient as well as economical and environmentally-friendly method to remove solids when treating process and waste waters. The MP-BF sieve-belt filter is a solution suitable for filtering water in many areas and industrial sectors. Examples of application:

Municipal wastewater treatment plants

Requirements for wastewater filtration depend on the actual level of the treatment process. The MP-BF sieve-belt filters are supplied with sieves with various porosity options, for instance:

- Entry screens (1,000–5,000 µm)

- Preliminary treatment (100–500 µm)

- Tertiary or final treatment (40–60 µm)

The removal of solids in wastewater treatment plants increases the efficiency of the treatment process. Solid biological substances are suitable for further processing, for instance, in biogas stations.

Food-processing industry

The removal of solids within productions lines in:

- slaughterhouses

- dairies

Industrial filtration

Preliminary treatment of surface waters to prevent unintentional leakage of substances into the sewerage system. Filtration of rinse waters.

For instance, suitable for:

- recycling lines for scrap material

- Zoos and natural parks

Aquaculture

Inland and coastal fish farms use sieve-belt presses for:

- preliminary treatment and primary filtration

- sludge thickening/dewatering

- drum filter concentrated rinsing

Belt filter - MP-BF

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h