Sludge treatment is no longer just about removing water - today it's about saving costs, energy and space. Where conventional presses are running out of options and conventional dryers are becoming pointless due to their energy consumption, electroosmosis dewatering is coming in. New technology.

A new standard.

Efficient sludge treatment is now the No. 1 topic for wastewater treatment plant operators and industrial companies alike. What is their goal? To achieve the highest possible sludge dewatering at minimum cost. Traditional mechanical dewatering can only increase the dry matter content to 20-25%, while conventional thermal sludge dryers achieve better results, but at the cost of enormous energy consumption. This is where electroosmotic dewatering comes in.

Why electroosmosis?

Our journey towards this technology began last June when we were looking for ways to push the boundaries of what was possible in dewatering. After a thorough research of the market and technological possibilities, electroosmosis sludge drying came our way, which stands out for its significantly lower energy consumption than conventional thermal dryers. This technology, which we eventually (very enthusiastically) chose, has been in development for more than 25 years in the laboratories of a South Korean company and has been operating successfully in the USA for several years.

Today we finally have it in the Czech Republic - and the results? Above expectations.

What can electroosmotic drainage do?

We have installed the device in semi-operational conditions at the wastewater treatment plant in Letovice, where testing and a practical demonstration of its operation is underway.

What have we found? (but we knew very well what we were getting into - and why we wanted it)

- Increase in dry matter content - from 20% to 60% in 3.5-4 minutes.

- Volume reduction - from 200 kg of sludge mass to 85 kg (i.e. 115 litres of water removed).

- Energy efficiency - 0.2 kWh/kg of water removed (up to 5 times lower than conventional dryers).

- Sludge sanitation - electroosmosis disrupts the cellular structures of microorganisms, which means the elimination of pathogens and bacteria.

- Space-saving solution - the entire system fits into a container the size of a standard garage (4 × 6 m).

- Minimal odour and dust - also suitable for areas with dense housing.

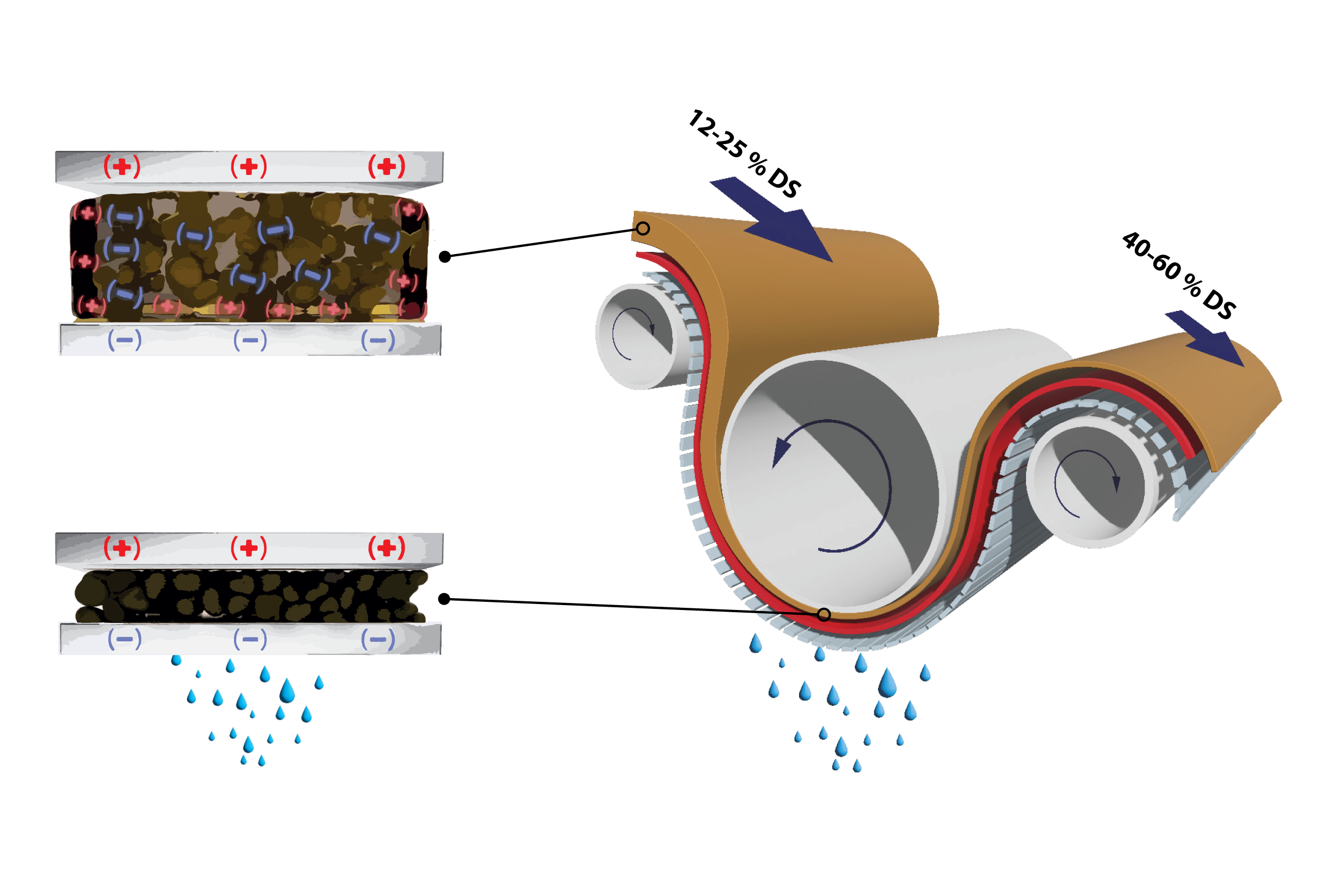

How does it work?

The process of electroosmosis dewatering is based on the use of an electric current to separate water from the sludge mass. The sludge first passes through a mechanical dewatering process on an MPW-201 auger dewatering machine (or alternative mechanical dewatering technology), which achieves an output of 30-40 kg dry solids per hour (i.e. 200-500 kg sludge cake). This partially dewatered material then enters the electroosmosis plant where the water content is significantly reduced within minutes.

Not only is this process fast, but it is also extremely energy efficient - while conventional thermal sludge drying requires 650-800 W/kg of removed water, electroosmosis operates at only 200 W/kg.

Unique technology (not) available in Europe

This innovation is attracting attention - water plant operators, designers and owners of treatment plants who come on excursions and see the benefits for themselves. It is a technology that no one else in Europe offers yet - and its potential is huge.

- Cost savings through lower energy consumption.

- Easier disposal or recycling of sludge due to significantly lower volume.

- Possibility of better use of sludge - for example as fuel or soil substrate

The future belongs to electroosmosis

Electroosmotic dewatering represents a new standard in sludge management. Trust us, this technology is the way forward.

Want to know more?

We invite you to take a tour directly to Letovice, please contact us.