Solenoid valves

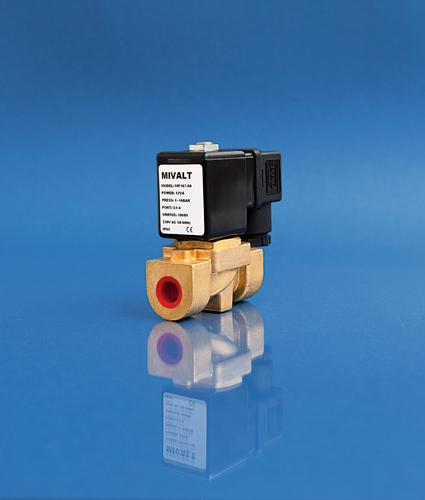

MP 167

Inquiry- indirectly driven 2/2 valves

- high reliability, long life

- medium: air/water

- working pressure 0,5–16 Bar

- maximum pressure: 16 Bar (1,6 MPa)

- ambient temperature: -20 ÷ +55 °C

- fluid temperature: -25 ÷ +90 °C

- medium viscosity < 20 cSt

- consumption 9 Watt

- el. connection: ISO4400, IP65

- voltage tolerance: ± 10 %

MP 167

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

- series of pseudo-directly driven stainless steel 2/2 valves

- works from zero pressure

- membrane directly controlled by core of coil over spring

- high reliability, long life

- medium: air/water/oil up to 40 cSt

- working pressure: air 0–10 Bar, water, oil: 0–7 Bar

- maximum pressure: 10 Bar (1 MPa)

- ambient temperature: -5 ÷ 55 °C

- medium temperatures: for NBR membranes -10 ÷ +85 °C, for Viton – water -10 ÷ +95 °C – air -25 ÷ +140 °C (for steam only up to 2,5 Bar, +140 °C with HT coil – not standart)

- material of body: brass (standard), stainless steal – suffi x S

- sealing: NBR – standard, VITON – suffi x V, EPDM suffi x E

- normally closed – standard, normally open – suffi x K

- voltage options: AC230 V 50/60 Hz, AC24 50/60 Hz, DC24, DC12

- el. connection: ISO4400, IP65

- voltage tolerance: ± 10 %

MP-W

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

MPW 22 2/2, MPW 23 2/3

Series MPW 22 – 2/2 directly driven stainless steel valve.

Series MPW 23 – 3/2 directly driven stainless steel valve.

- body material: stainless steel 304

- valve can operate in any position

- high reliability, long life

- medium: air, water

- maximum pressure: 60 Bar (6 MPa)

- ambient temperature: -40 ÷ +60 °C

- fluid temperature: -40 ÷ +180 °C

- sealing: FPM

- medium viscosity < 20 cSt

- response time: open 5–20 ms

- connector specifi cation/el. connection: DIN4400/EN175301-803, IP65

- standard voltage 230 V/50 Hz, possibility of 12VDC, 24VDC, 24VAC

- power consumption 19 VA

- voltage tolerance: ±10 %

MPW 22 2/2, MPW 23 2/3

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

MPW 156-2 2/2, MPW 156-3 2/3

Series MPW 156-2 – 2/2 directly driven stainless steel valve.

Series MPW 156-3 – 3/2 directly driven stainless steel valve.

- body material: stainless steel 304

- valve can operate in any position

- high reliability, long life

- medium: air, water

- working differential pressures: 0–7 Bar for 2/2, 0–4 Bar for 3/2

- max. static pressure: 16 Bar (1,6 MPa)

- ambient temperature: -20 ÷ +60 °C

- fluid temperature: -20 ÷ +120 °C

- connection G1/4”, orifi ce DN 2 mm

- KV factor = 2,4 l/min

- sealing: FPM

- medium viscosity: < 20 cSt

- response time: open 5–20 ms

- standard voltage 230 V/50 Hz, 12VDC, 24VDC, 24VAC

- consumption 7 VA for AC, 5 Watt for DC

- connector specifi cation/el. connection: DIN43650, IP65

- voltage tolerance: ±10 %

MPW 156-2 2/2, MPW 156-3 2/3

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

MP-T

Inquiry- directly driven 2/2 valve

- all teflon body

- PTFE separation membrane

- for aggressive chemicals or ozone

- response time: open 5–20 ms, close 25–100 ms

- el. protection class: IP65

- voltage tolerance: ± 10 %

MP-T

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

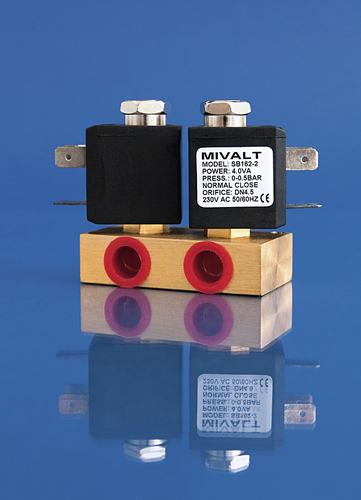

- high reliability, long life

- valve can operate in any position

- designed for air fl ow

- differential pressure: 0–0,5 Bar

- maximum pressure: 2 Bar

- ambient temperature: -20 ÷ +55 °C

- fluid temperature: -25 ÷ +90 °C

- KV factor 5,1 l/min

- response time: open 5–20 ms

- sealing: NBR

- orrifice DN 4,5 mm

- consumption 5 Watt

- specifications of connector/el. connection: DIN43650, IP65

- voltage tolerance: ± 10 %

MP 162/2

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

- solenoid 3/2 distribution valve is used for controlling flow of air and water at low pressures – up to 0,5 bar

- robust design

- KV factor 33 l/min

- response time: open 5–20 ms

- possibility of connecting two or more of these valves in one valve island

- horizontal connection is input

- vertical bottom output is normally open

- vertical top output is normally closed

- upon switching on the coil (energizing), the valve switches and closes the bottom output and opens the top one

- voltage tolerance: ± 10 %

MP 160-1

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

- usage: controlling fluid flow at low pressures up to 0,5 Bar

- compact, lightweight

- KV factor 33 l/min

- response time: open 5–20 ms

- horizontal connection is input

- vertical bottom output is normally open

- vertical top output is normally closed

- upon switching on the coil (energizing), the valve switches and closes the bottom output and opens the top one

- voltage tolerance: ± 10 %

MP 160

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

- usage: water, gas and light oils up to 40 cSt

- piston principle, smooth switching, high reliability

- maximum operating pressure 5 MPa

- working differential pressure 1–50 Bar (0,1–5 MPa)

- fluid temperature: 0 ÷ + 90 °C

- ambient temperature: -20 ÷ + 55 °C

- long life: 1 500 000 cycles/20 000 hours continous operation

- el. connection corresponds ISO4400/ EN175301-803/A

- el. protectiono class IP65

- voltage tolerance: ± 10 %

MP 116-5

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

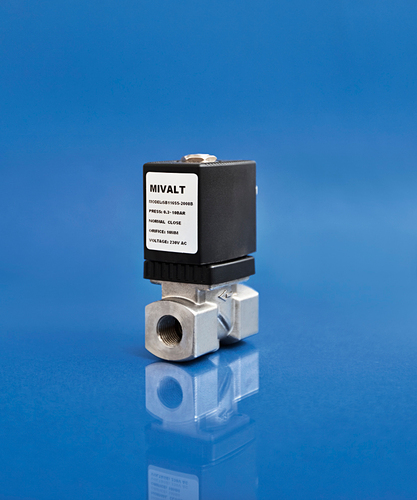

- usage: water solutions, light oils up to 40 cSt and inert gases

- low noise with anti-shock effect for water, without vibrations

- coil embedded in thermoplastic material

- body of valve made from brass

- working differential pressure 0,2–10 Bar, • maximum pressure 16 Bar (1,6 MPa)

- fluid temperature: -10 ÷ + 90 °C

- ambient temperature: -10 ÷ + 55 °C

- long life: 1 500 000 cycles/20 000 hours continous operation

- el. connection corresponds ISO4400/ EN175301-803/A

- el. protectiono class IP65

- voltage tolerance: ± 10 %

MP 116

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h

MP 163, MP163-4

Serie MP163 - directly driven 2/2 valves.

Serie MP163 - directly driven 4x 2/2 solenoid valves island.

- medium: air

- differential pressure: 0–0,35 Bar

- maximum pressure: 1 Bar

- ambient temperature: -20 ÷ +55 °C

- fluid temperature: -25 ÷ +90 °C

- KV factor 21 l/min

- response time: open 5–20 ms

- sealing: NBR

- valve can operate in any position

- high reliability, long life

- orifice DN 12 mm

- consumption 9 Watt

- el. connection: ISO4400, IP65

- voltage tolerance: ± 10 %

MP 163, MP163-4

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h